Technology: Laptops, Mobile Phones, and Gaming Consoles

Thermal grease plays a crucial role in modern technology by managing heat in compact and high-performance devices such as laptops, mobile phones, and gaming consoles. As devices get smaller and more powerful, they generate more heat. Without proper thermal management, this heat can lead to performance throttling, reduced lifespan, and potential device failure. In laptops, thermal grease is applied between the CPU/GPU and the heat sink. This ensures efficient heat transfer away from the processors, allowing for sustained performance even during intensive tasks like gaming, video editing, or running complex simulations. Mobile phones, especially smartphones, also rely on thermal grease to keep their processors cool. With the advent of 5G technology and the increasing demand for high-speed processing, effective thermal management is more important than ever. The use of thermal grease helps maintain optimal performance while ensuring user safety. Gaming consoles such as Xbox and PlayStation (PS5) are known for their powerful hardware and the heat they generate during extended gaming sessions. Thermal grease in these consoles is essential to ensure that the processors and graphic units remain cool, preventing overheating and ensuring a seamless gaming experience. By using high-quality thermal grease, manufacturers can maximize the efficiency of the cooling system, allowing for quieter operation and longer device lifespan.

Automotive: Electric Cars and Battery Management

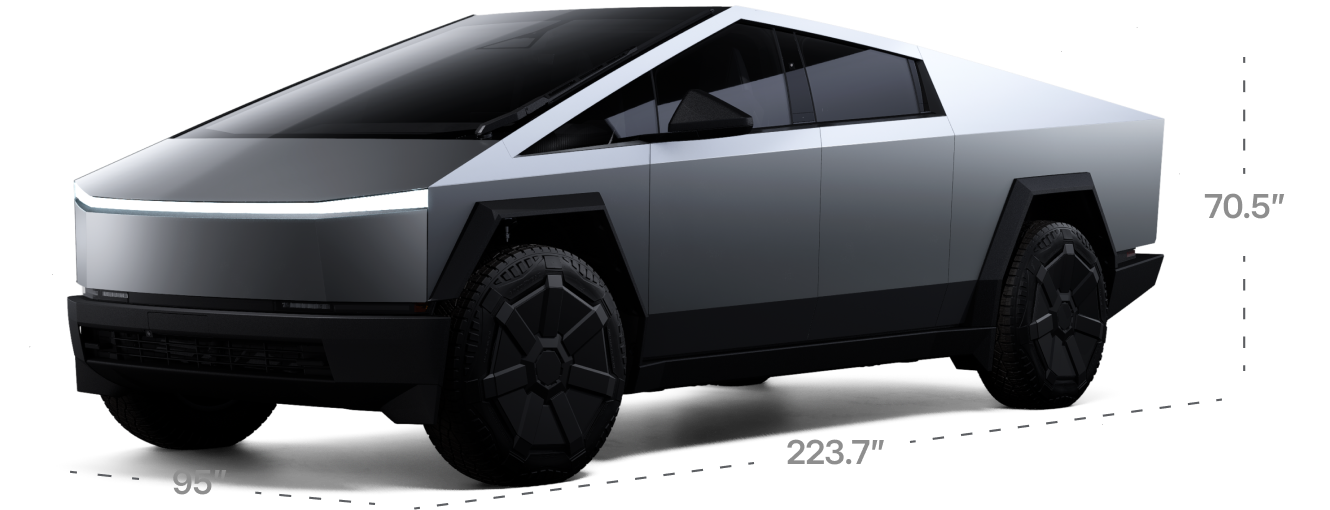

The automotive industry is rapidly evolving with the increasing adoption of electric vehicles (EVs). One of the biggest challenges in EVs is thermal management, especially in batteries and power electronics. Thermal grease is an essential component in managing the heat generated by these components, ensuring the vehicle's performance, safety, and longevity. In electric cars, thermal grease is used to enhance heat transfer between battery cells and the cooling systems. Batteries are sensitive to temperature changes, and maintaining an optimal temperature is crucial for their efficiency and lifespan. Thermal grease helps in dissipating the heat generated during charging and discharging cycles, ensuring that the batteries operate within a safe temperature range. This not only improves the efficiency of the battery but also extends its life. Electric cars also use thermal grease in power electronics such as inverters, converters, and motor controllers. These components are responsible for managing the power flow from the battery to the motor and other systems. By ensuring effective heat transfer, thermal grease prevents overheating, reduces thermal resistance, and enhances the overall efficiency of the vehicle's power management system. Moreover, in traditional combustion engine vehicles, thermal grease is used in engine control units (ECUs) and other electronic components to ensure reliable performance and longevity.

Data Centers and Servers: Enhancing Thermal Conductivity

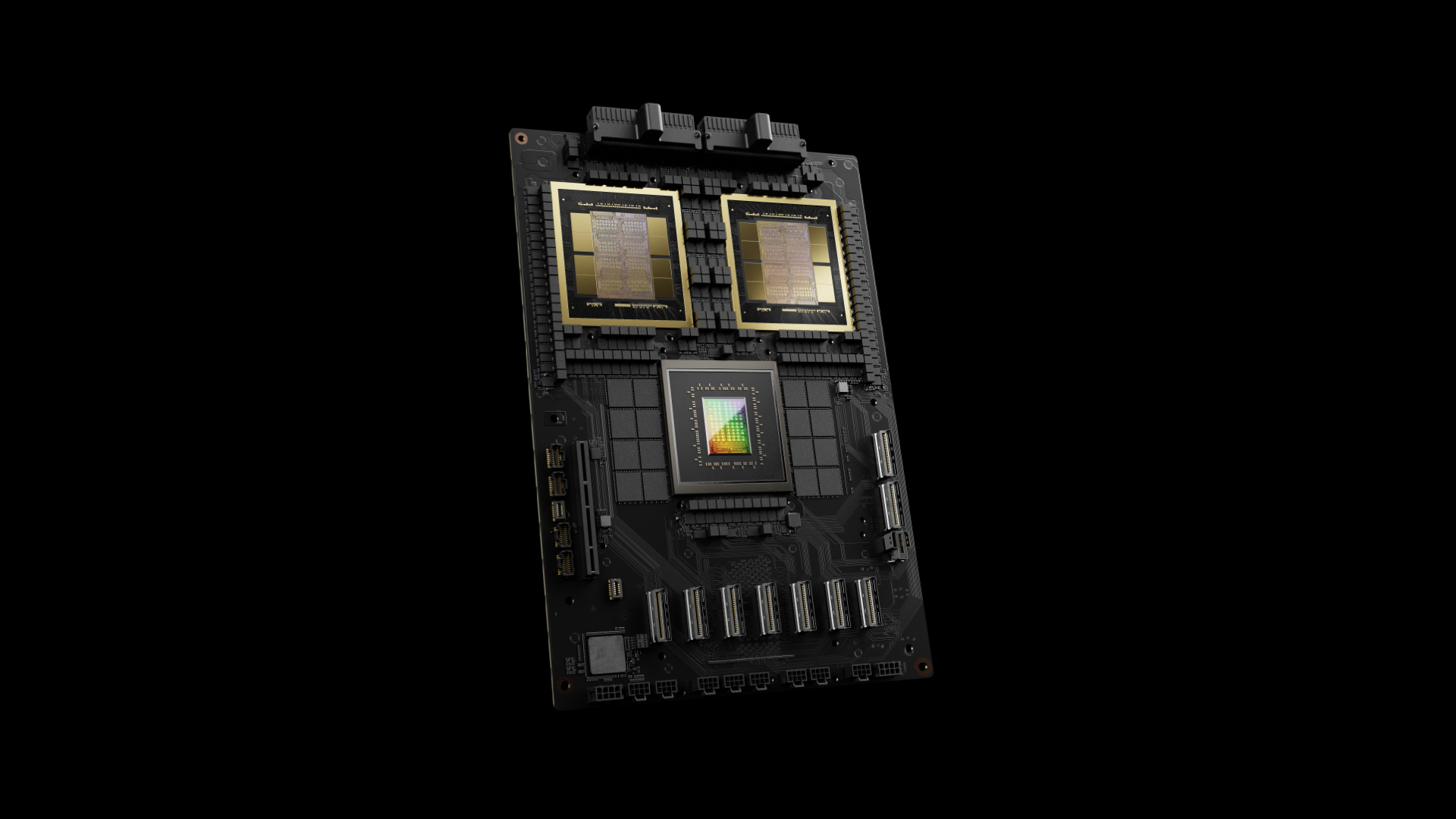

Data centers and servers are the backbone of modern digital infrastructure, handling vast amounts of data and running complex applications. These systems generate a significant amount of heat due to the high processing power of CPUs and GPUs. Effective thermal management is critical in these environments to prevent overheating, maintain performance, and ensure system reliability. Thermal grease is an integral part of the thermal management system in servers and data centers. It is applied between the processors and heat sinks to enhance heat transfer and reduce thermal resistance. This ensures that the processors can operate at their maximum potential without the risk of thermal throttling or damage due to overheating. The use of high-quality thermal grease in data centers can significantly improve cooling efficiency, leading to reduced energy consumption and lower operating costs. Additionally, in environments where servers are stacked closely together, such as in cloud computing and high-performance computing (HPC) setups, maintaining an optimal temperature is even more challenging. Thermal grease helps in managing the thermal load effectively, ensuring consistent performance and preventing downtime. By improving the thermal conductivity between components, thermal grease contributes to the overall stability and efficiency of data center operations.

Custom Applications and Industry-Specific Uses

Thermal grease finds applications beyond the standard consumer electronics and automotive industries. It is widely used in specialized fields such as aerospace, medical devices, and industrial machinery, where thermal management is crucial for performance and safety. In the aerospace industry, for example, thermal grease is used in avionics and satellite systems. These components operate in extreme conditions, and effective heat management is essential to ensure their functionality and longevity. Thermal grease helps in maintaining the temperature of critical components, ensuring that they operate within their specified limits even in harsh environments. In the medical field, thermal grease is used in imaging equipment such as MRI machines and ultrasound devices. These machines generate significant heat during operation, and thermal grease ensures that the sensitive electronic components remain cool and functional. This not only enhances the performance of the equipment but also extends its operational life, reducing maintenance costs. In industrial machinery, thermal grease is used in power electronics and control systems to manage heat and ensure reliable operation. Whether in robotic arms, CNC machines, or automated assembly lines, thermal grease plays a vital role in maintaining the performance and efficiency of these systems. Its ability to provide consistent thermal conductivity across various applications makes it a versatile solution for industry-specific needs.

Environmental Impact and Sustainability

As the world moves towards more sustainable and eco-friendly technologies, the role of thermal grease in reducing environmental impact is becoming increasingly significant. By enhancing the efficiency of thermal management systems in various applications, thermal grease helps in reducing energy consumption and minimizing the carbon footprint of electronic devices and vehicles. In electric vehicles, for instance, effective thermal management ensures that the battery operates efficiently, extending its lifespan and reducing the need for frequent replacements. This not only reduces the environmental impact associated with battery production and disposal but also contributes to the overall sustainability of electric mobility. Similarly, in data centers, the use of thermal grease in enhancing cooling efficiency leads to lower energy consumption, reducing the carbon footprint of these facilities. Moreover, the development of eco-friendly thermal greases with non-toxic and recyclable materials further aligns with the global push towards sustainability. By choosing thermal greases that are environmentally friendly, manufacturers can contribute to a greener and more sustainable future. At Deep Material, we are committed to developing products that not only meet the highest performance standards but also adhere to our values of environmental care and responsibility.